What is Fourier?

Fourier usually refers to Jean-Baptiste Joseph Fourier, a French mathematician and physicist in the late 18th and early 19th centuries, who is renowned for proposing “Fourier Analysis”. His core contribution, Fourier Analysis, is a mathematical tool. Its core idea is: any periodic complex signal or function can be decomposed into the superposition of a series of simple sine waves (or cosine waves). This theory is widely applied in fields like signal processing (e.g., audio, images), physics, and engineering. For instance, the Wi-Fi signal processing and image compression technology we use daily are both based on the principles of Fourier Analysis.

How is Fourier Analysis applied in the gear industry?

Fourier Transform can decompose time-domain signals such as gear vibration and noise into frequency-domain signals, thereby revealing their inherent frequency structure and periodic characteristics.

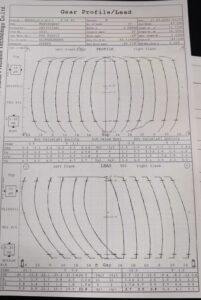

In gear manufacturing, by performing Fourier Transform (FFT) on gear tooth surfaces, we can quickly verify whether the specific sensitive order of a gear meets the requirements. Tooth surface Fourier inspection is a supplement and extension of the tooth profile and tooth trace report. Based on the measured tooth surface curve, it decomposes the curve into sine waves of different orders through Fourier Transform, then evaluates the frequency-domain image, which can be used to screen out defective parts that affect NVH (Noise, Vibration, and Harshness).

In terms of gear fault diagnosis, Fourier Analysis can effectively separate and quantify the frequency characteristics mixed in the time domain, enabling the identification and severity assessment of gear faults such as wear and tooth breakage. For example, meshing frequency and its harmonics, sidebands, and fault characteristic frequencies can all be extracted through Fourier Analysis. These characteristic frequencies can reflect issues such as uneven load distribution on the tooth surface, gear wear, and shaft misalignment.

1. Adjust the grinding speed: During the gear grinding process, the speed of the grinding tool affects grinding vibration, which in turn influences order errors. Ghost orders can be adjusted by changing the grinding speed to disrupt the grinding vibration. For example, in a certain case, the grinding speed was changed from 4425 rpm to 4625 rpm, and then to 4825 rpm, to observe the changes in ghost orders in the Fourier report.

2. Adjust the Z-axis feed rate per revolution in the fine grinding stage: The Z-axis feed rate per revolution in the fine grinding stage is also related to grinding vibration. In the same case mentioned above, the Z-axis feed rate per revolution in the fine grinding stage was adjusted from 0.25 mm to 0.2 mm, and then to 0.152 mm, ultimately eliminating the 113th-order ghost order in the tooth trace.