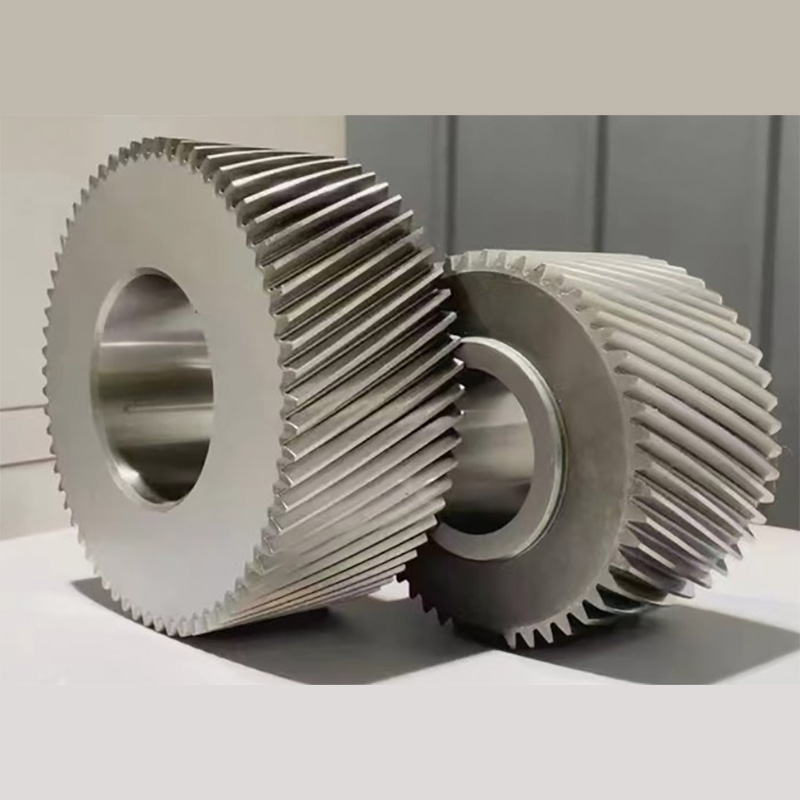

1. Vibration-Reducing Design: Optimized tooth profiles minimize harmonic resonance, proven in industrial case studies. 2. High-Temp Alloy Construction: 18CrNiMo7-6 steel hardened to 60 HRC withstands 200°C continuous operation. 3. Energy Efficiency: Helical gears reduce friction losses by 18% compared to standard spur designs. 4. OEM Compatibility: Precision-machined for seamless integration with Kaeser, MAN Energy, and Siemens systems.

Experience

OEM ODM

QC

Factory

Workforce

Certified

Team

Service

Capacity

Delivery

Compressor Gear Optimization

Implement our patented asymmetric tooth design, reducing harmonic resonance by 42% (validated in field studies).

Use ISO VG 320 synthetic oil with anti-wear additives and conduct monthly particle contamination checks.